FROM PRECISE CLEANING TO PERFECT FINISH

Metal Cleaning

Perfectly clean metal surfaces are critical to each step of metal processing to assure the success of the total manufacturing process. The cleanliness of high-quality components has become an essential quality attribute.

This concept provides an overview on trends and market observations in the metal surface cleaning industry, an overview on the specific cleaning needs, and offers sustainable solutions to maximize the efficiency of metal cleaning formulations.

Solutions found within this concept:

- Identify the types of soil removal, particular applications, and effective cleaning products customized for metal cleaning or processing

- Trends in metalworking surfactants and the claims metal cleaning formulators look for in the industry

- Innovative product combinations with guideline formulation know-how

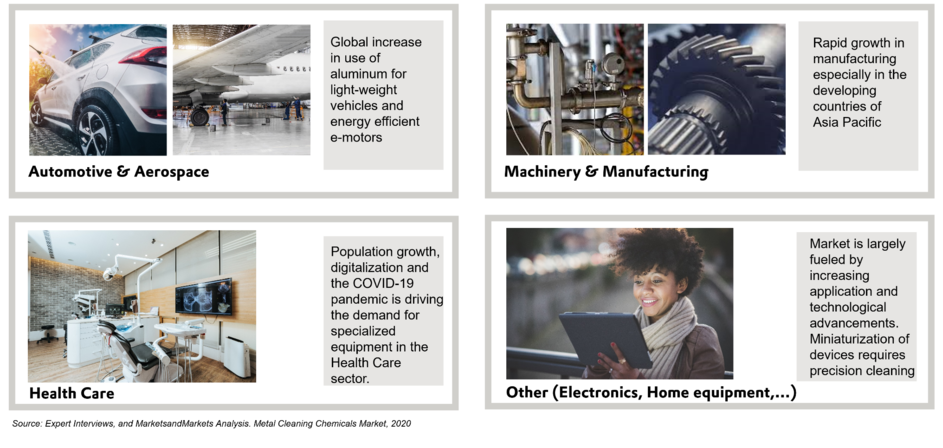

Today, metal cleaning chemicals enjoy increased demand from automotive, aerospace, electronics & technology, manufacturing, and many other industries, due to the increasing consumption of non-ferrous and ferrous metals. The increasing demand for metals in end-use industries requires specific surface preparation, cleaning associated with the annealing process, or pretreatment cleaning solutions, as certain metal surfaces might react differently with different materials and formulations.

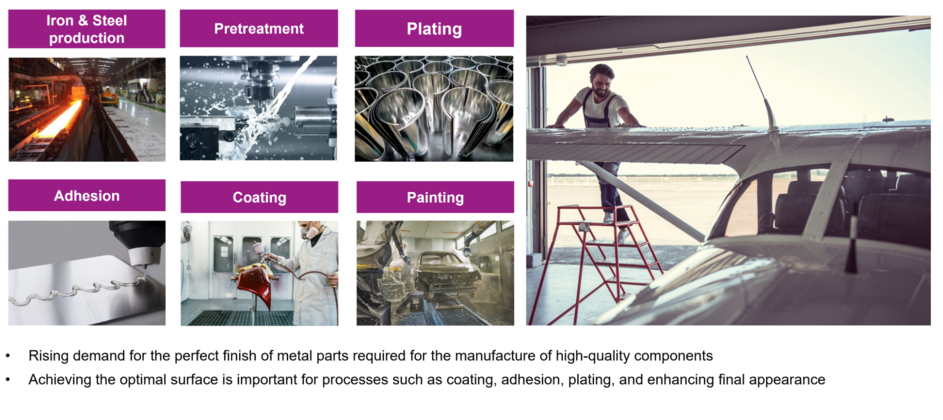

The rising demand for the perfect finish of metal parts are required for the manufacture of high-quality components. Achieving the optimal surface is important for processes such as coating, adhesion, plating, and enhancing final appearance.

Additionally, the cleanliness of the metal surface finish is especially critical for electronics and metal components manufacturing because cleaning products may react differently to varying grades of aluminum or stainless steel, which can result in wear, etching, tarnish, or corrosion of the material.

Particularly acids, solvents or other abrasive chemicals can affect desired metal cleanliness or metal surface finish. It is also essential to consider the best metal cleaner or polish for associated componentry or coatings, such as silicones, plastic, and rubber seals, which can suffer during various surface treatment methods and cleaning surfactant processes.

Continuous demand from these rapidly evolving industries, like electronics and technology, drives cleaning chemistries, processes, and products that rapidly grow to adapt to these changing requirements while achieving a superior streak-free shine free of watermarks.

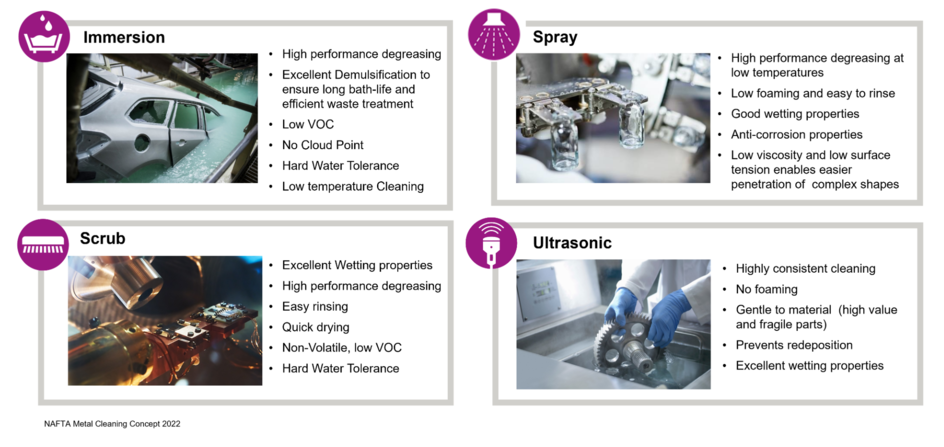

Different cleaning methods, such as immersion, spray or rinse, scrub or ultrasonic, and require additional attributes from cleaning chemicals. As a result, Evonik offers exceptional, sustainable solutions categorized into four sections within the Metal Cleaning concept portfolio:

The best cleaning performance, when only the best metal surface finish will do.

The sustainable combination of cleaning performance, mildness and environmental compatibility

Reduce overall (or next-time) cleaning time by enabling quick drying of parts and improved rinsing of cleaning formulations

Improve metal surface cleanliness and for specific manufacturing needs, such as sensitive metal surface cleaning or lubrication needs, even odor control necessary during the metal cleaning process